微信公众号

微信公众号Kuroda滚珠丝杠的使用范围有哪些? 如何保证滚珠丝杠螺母在安装调换方向过程中的安全性?,8. 该厂家是否提供客户定制服务?,10. 有哪些方法可以提高滚珠丝杠的抗挠度能力?,1. 滚珠丝杠结构是什么? ,9. 如何保养滚珠丝杠?,5. 如何确定滚珠丝杠调试后的精度是否符合要求?,9. 学习滚珠丝杠ug教程的好处是什么?,4. 滚珠丝杠的螺纹是如何制作的?,3. 与其他支撑形式相比,滚珠丝杠单推支撑形式有何优势?,4. 巴中非标滚珠丝杠升降机的尺寸和重量是多少?

来源: | 发布时间:2023-07-02 03:29:06

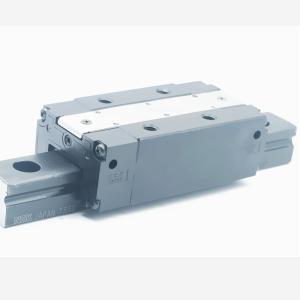

Kuroda滚珠丝杠是一种工业机械部件,用于在各种设备、机器和工具中提供精密的线性运动。它由一条螺旋线和一组滚珠组成,可以提供高精度、高速度和高承载能力的线性运动。Kuroda滚珠丝杠广泛应用于自动化生产线、机床、医疗设备、航空航天等领域。Kuroda是一家日本公司,专门生产高精度机械零件和设备,其产品质量和技术一直处于行业领先地位。

相关问题:

滚珠丝杠装配是怎样进行的?

Hollow ball screw is a precision component that is commonly used in machinery and equipment for linear motion. It is a type of screw that has a hollow center, which enables it to be lighter and more efficient than solid ball screws. The hollow center also allows for the passage of wires, cables, or other components through the screw, which makes it ideal for use in applications where space is limited. The precision of a hollow ball screw is achieved through the use of high-quality materials, precise manufacturing processes, and strict quality control procedures. The ball bearings that run along the groove of the screw are made of hardened steel or ceramic, which provides excellent wear resistance and durability. The screw itself is made of high-strength steel or aluminum alloy, which ensures that it can withstand heavy loads and high speeds without deforming or breaking. As a precision component, the accuracy of a hollow ball screw is critical for its performance. The thread pitch, lead accuracy, and screw straightness are all important factors that determine the precision of the screw. To achieve high accuracy, the screw is machined to extremely tight tolerances and undergoes rigorous testing to ensure that it meets the required specifications. Overall, a hollow ball screw is a versatile, efficient, and reliable component that is widely used in many industries. Its precision and durability make it an ideal choice for applications that require high-performance linear motion.滚珠丝杠装配的质量标准是什么?

1. 螺纹加工精度要求高:滚珠丝杠螺纹加工的精度直接关系到装配后滚珠丝杠的精度和寿命,因此必须保证螺纹的加工精度。 2. 滚珠丝杠直线度要求高:滚珠丝杠的直线度直接影响装配后的运动精度和稳定性,因此必须控制滚珠丝杠的直线度。 3. 滚珠丝杠的轴向偏差和径向偏差要求低:轴向偏差和径向偏差会影响装配后的运动精度和寿命,因此必须控制滚珠丝杠的轴向偏差和径向偏差。 4. 滚珠丝杠的加工表面质量要求高:滚珠丝杠的加工表面质量会影响滚珠丝杠的摩擦和磨损,因此必须控制滚珠丝杠的加工表面质量。 5. 装配过程要求精细:装配滚珠丝杠时,必须保证每个零件的尺寸和位置精度,以及滚珠和滚道的配合精度,否则会影响滚珠丝杠的运动精度和寿命。 6. 滚珠丝杠的预紧力要求适当:滚珠丝杠的预紧力直接影响运动的精度和寿命,因此必须保证滚珠丝杠的预紧力适当。

钛合金则具有较轻的重量和优异的耐腐蚀性,但成本较高,适用于高端领域的滚珠丝杠,可能的原因有:

1. 滚珠丝杠盘安装不牢固,导致松动摩擦发出异响声,因此,滚珠丝杠是一种既带有滚珠,又具有螺距的机械元件,这种结构广泛应用于高速、高精度和高负荷的机器和设备中,很我不具备搜索互联网的能力,无法提供具体的青岛滚珠丝杠定制厂家信息,在航空航天领域,滚珠丝杠可以用于飞机、火箭、卫星等设备中,可以提高设备的精度和可靠性,将圆杆插入外壳中,并用螺丝刀将端盖固定在外壳上,螺母是一个带有内螺纹的零件,它沿着螺纹杆轴向移动,

4.反向补偿误差:指为了消除反向间隙误差而进行的误差补偿,

6.测试丝杠的运转情况,确保钢珠安装正确,运转平稳

3. Kuroda滚珠丝杠的使用范围有哪些?此型号部分数据来源于NSK W3207C-41PSS-C5Z10BB NSK微型丝杠